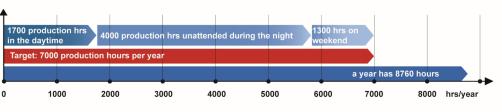

Use your time bands productively with Depot-Line 7000!

Depot-Line 7000 is very suitable for the automation on sliding head lathe, turning shop and other machine tools. You can also benefit from production optimization thanks to SPC controls!

- During the night and at the weekend

- Up to 16 hours autonomic work

- Target 7000 hours per year

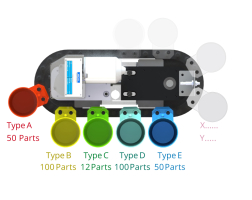

- Individually adjustable number of Depot-Line 7000 storage spaces

- Optimised production planning for Depot-Line 7000

- Single turned parts and small serie production during the day

- Long-running turned parts overnight

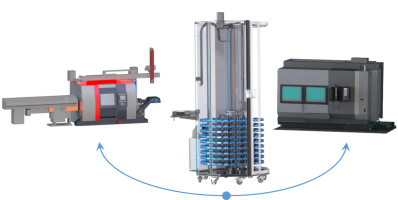

- For the automation on machine tools (sliding head lathe) and turning shops

Your production optimisation with the use of Mecha Depot-Line 7000

Depot-Line 7000 creates a large potential for rationalization on machine tools such as sliding head lathe, multi-spindle machines, short turning machines, bar/milling and turning centers as well as cylindrical grinding and centerless grinding machines. Thanks to automation, statistical process control (SPC), a reduction in the loss of parts and a guaranteed contact-free separation and storage of turned parts, production optimization can be guaranteed.

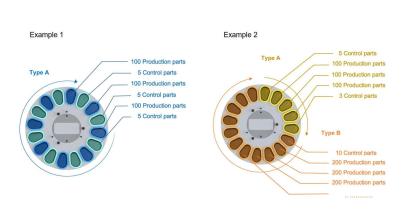

Depot-Line 7000 enables automatic implementation of quality control plans and statistical process controls (SPC)

- Guarantee the separation of turned parts with no human influencing factor

- Number of control parts and interval can be individually programmed

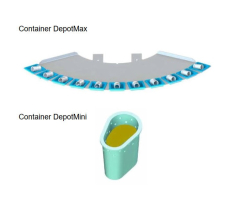

Depot-Line 7000 protects the surfaces of turned parts from sliding head lathe, turning shops and other machine tools

- Parts are placed non-contact in single or defined batch sizes in oil to limit the risk of material damage

Depot-Line 7000 enables autonomous operation of the Mecha part separators

- Simply retrofit to existing machines, as the parts separators are operated electrically and autonomously

- Optional machine interface (ready for operation, memory full)

- Same workpiece storage can be used on multiple machines (turning shops, sliding head lathe, machine tools)

Depot-Line 7000 offers parts separation and temporary workpiece storage

- Container DepotMax: Parts are stored individually

- Container DepotMini: Parts are stored in oil in defined batch sizes

Depot-Line provides all prerequisites for the production of parts families

- Separated storage of different parts families

- When switching program to CNC control - container change with M code

- Parts are placed non-contact in single or defined batch sizes in oil to limit the risk of material damage

Depot-Line 7000 prevents the loss of workpieces

- Loss-free parts unloading from the machine using vacuum suction