DepotMini - A part separator for statistical process control (SPC) for the purpose of quality inspections

Statistical process control (SPC control) of manufacturing and measuring processes is used to achieve low-variability in the production of micromechanical components and workpieces.

DepotMini is a specially designed part separator for small parts and micro-parts and guarantees quality control with traceability of the random sampling. The production process can thereby be adapted in the case of deviations and as required and the desired quality of the workpieces achieved. This allows for a more economical production and a automation on sliding head lathe, turning shops and machine tools. The frequency and size of random sampling can be variably set by means of a further sequencing process and enables the measurement control of the random sampling adapted to the requirements.

Compact and small

DepotMini can be integrated into a production process without much expenditure and supports a quality management system.

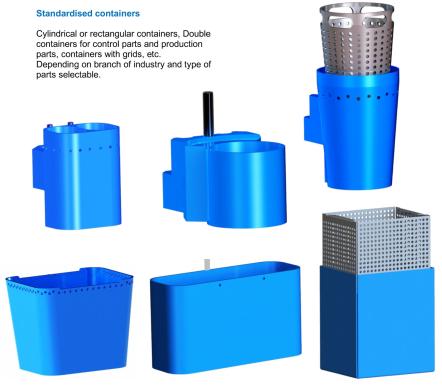

DepotMini is placed by the workpiece output channel and can be retrofitted to any sliding head lathe, turning shops or machine tools. Thanks to its compact design, the DepotMini can simply be mounted on a different machine as required. DepotMini is available in 2 designs; in version with chain or in a round version as a rotary table. Plastic containers in various different sizes, custom-made, to intake the workpieces and random samples can be attached to both designs and dismounted again for further processing and measurement control of the workpieces or random samples. DepotMini is suitable for small parts and micro-parts.

All advantages at a glance:

- Enables statistical process control (SPC control)

- Traceability of the random samples for quality control

- Frequency and size of random sampling can be variably set by means of a further sequencing process

- Supports a quality management system

- Can be integrated in a production process without much effort

- For the automation on sliding head lathe, turning shops and machine tools

- Can be retrofitted to any processing machine with a parts output channel (small parts and micro-parts)

- Low investment costs

- Control system is independent of the processing machine

- No additional programming and retrofitting effort

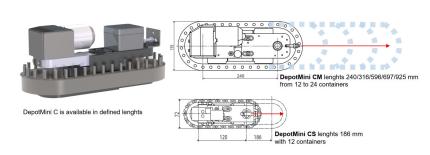

Overview of variants DepotMini C and DepotMini C V (with vacuum unit)

For product data sheets please click on the pictures!

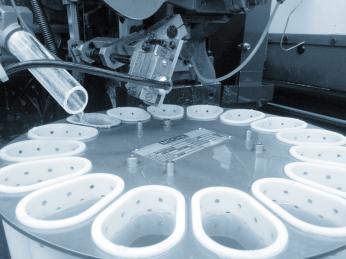

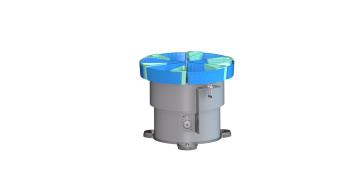

Overview of variants DepotMini R

For product data sheets please click on the pictures!

Überschrift

DepotMini R316

Small parts and micro parts are rinsed directly into the containers.

Überschrift

DepotMini C240

Integrated in the machine.

Überschrift

DepotMini C240 on Trolley

With drip tray, integrated control system and single or double containers for control and production parts.

DepotMini R212

Ø 200, 6 production parts containers and 6 control parts containers

DepotMini R316

Ø 300, 16 containers (e.g. 8 production parts containers and 8 control parts containers)

DepotMini R308

Ø 300, 8 containers (e.g. 5 production parts containers and 4 control parts containers)

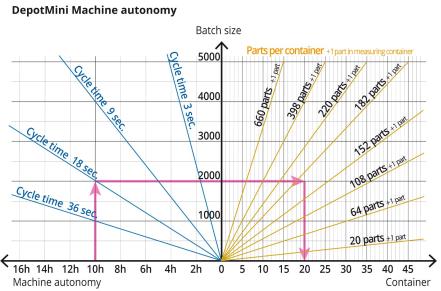

DepotMini - Machine autonomy

Standardised containers