DepotVacuum - The solution for safely vacuum unloading of small parts and micro-parts directly from the machine with vacuum extraction

In the manufacture of small parts and micro-parts with a diameter of 0.2 - 8.0 mm, parts unloading using a conveyor belt or parts slide as provided on the machine tool may cause a loss of parts up to 30% inside the tool. Delicate parts may also be damaged.

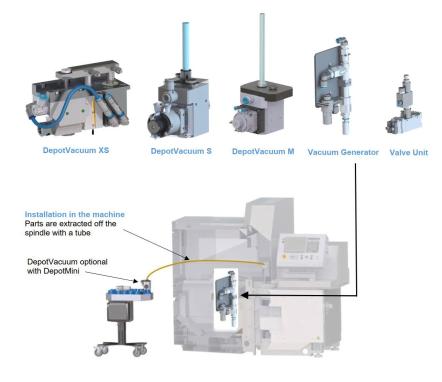

To solve this problem, Mecha has developed the DepotVacuum. It enables a direct vacuum unloading of small parts or micro-parts from inside the machine with a vacuum hose and deposits them in the DepoMini containers. The vacuum is generated by a pneumatic vacuum unit and can be regulated depending on the suction strength required. A filter is fitted upstream of the vacuum generator to prevent a contamination, for example by metal shavings. This filter can be cleaned as needed and reused.

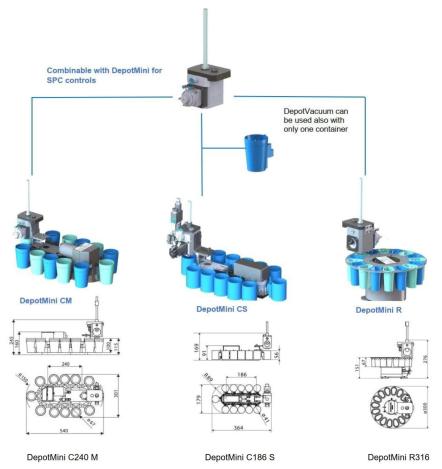

The DepotVacuum can be used with all DepotMini versions. Combined with a DepotMini, the DepotVacuum therefore also ensures a safely parts unloading of particularly fragile small parts or micro-parts and deposit them damage-free and traceable in a storage system.

Example application:

For small parts and micro-parts with diameter of 0.2 - 8.0 mm.

Benefits:

- Safe parts unloading of particularly fragile small parts and micro-parts

- Traceable and damage free parts storage when combined with a DepotMini

- Extraction hose length up to 1.5 m

Overview of DepotVacuum variants

DepotVacuum XS

| Part Ø mm | Length part mm | Hose Ø mm (outside) | Hose Ø mm (inside) |

| approx. 1.0 - 4 | up to max. 15 | 10 | 7 |

| 8 | 5.5 | ||

| 6 | 4 | ||

| 4 | 2.5 | ||

| 2 | 1.2 |

DepotVacuum S

| Part Ø mm | Length part mm | Hose Ø mm (outside) | Hose Ø mm (inside) |

| approx. 3 - 5 | up to max. 25 | 10 | 7 |

| 8 | 5.5 | ||

| 6 | 4 | ||

| 4 | 2.5 |

DepotVacuum M

| Part Ø mm | Length part mm | Hose Ø mm (outside) | Hose Ø mm (inside) |

| approx. 4 - 10 | up to max. 45 | 16 | 11 |

| 12 | 9 | ||

| 10 | 7 | ||

| 8 | 5.5 | ||

| 6 | 4 |

Hose from DepotMini into the machine

Hose in machine opposite the opposed spindle