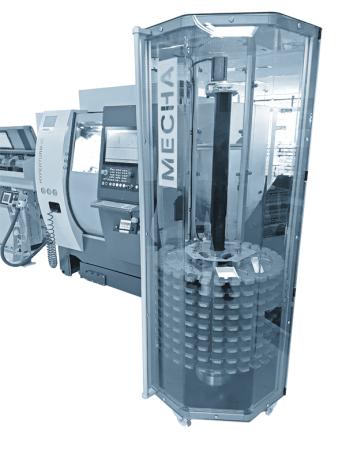

DepotMax the palletizer - the flexible and efficient workpiece storage system

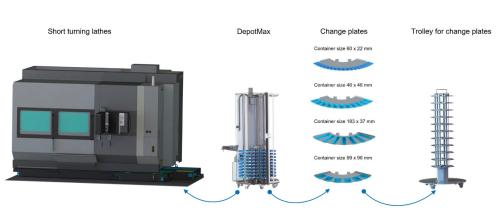

DepotMax is a compact and automatic workpiece storage system and palletizer, that carefully collects parts after machining using a feeder conveyor belt, and provides chronological interim storage in plastic containers. The patented "Butler" can automatically collect up to 600 workpieces, independently of their geometry and up to a size of 85 x 140 mm. The storage tower can be variably equipped with exchange plates and plastic containers. The palletizer DepotMax can be added to any fixed headstock lathes or bar milling centre and requires no set-up time. You can achieve short amortisation times, even for small batches.

Conventional extraction solutions usually result in unwanted side effects. Bulk materials can be difficult to trace and to avoid parts damage is not possible. Conveyor belts also do not allow traceability and require a large amount of space. Automatic extraction solutions, for example using robots, are associated with high investment costs and significant programming and re-tooling work. Similarly, workpiece changes can result in costly long downtimes. Ever increasing requirements for workpiece output in terms of precision, finish, and statistical process control (SPC) require solutions that treat your workpiece with the special care it deserves. For these requirements, MECHA has developed and manufactured the automatic workpiece system and DepotMax for palletization.

Advantages at a glance:

- Enables statistical process control (SPC) since the products can be stored in the order of production, thereby guaranteeing traceability

- Touch-free workpiece storage and palletization, preventing any scratching of the surface

- Automatic system

- Freely selectable placement on any CNC system (fixed headstock lathes, bar milling centre)

- Different workpiece geometries can be stored without the need for re-tooling

- No need for part-specific grippers

- Multiple workpiece types can be stored in the same storage tower

- Stackable containers for workpiece carriers

- Suitable for bulk materials with multiple parts per container and separation of control parts

- Avoid parts damage

- Adjustable storage capacity

- Independent of CNC control system

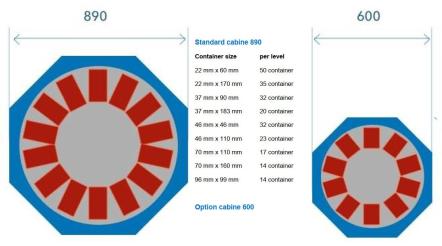

Overview DepotMax with variants of container

For detail drawing please click on the pictures!

DepotMax in use

Size of containers 183 x 37 mm

Operating panel with control

The touchscreen control panel is independent of the machining system. No interface to the machine tool (fixed headstock lathes, bar milling centre) is required. A sensor independently detects the parts to be stored and saves the filled container positions.

DepotMax - Comparison of the cabins

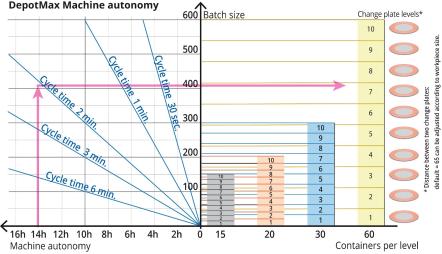

DepotMax - Machine autonomy